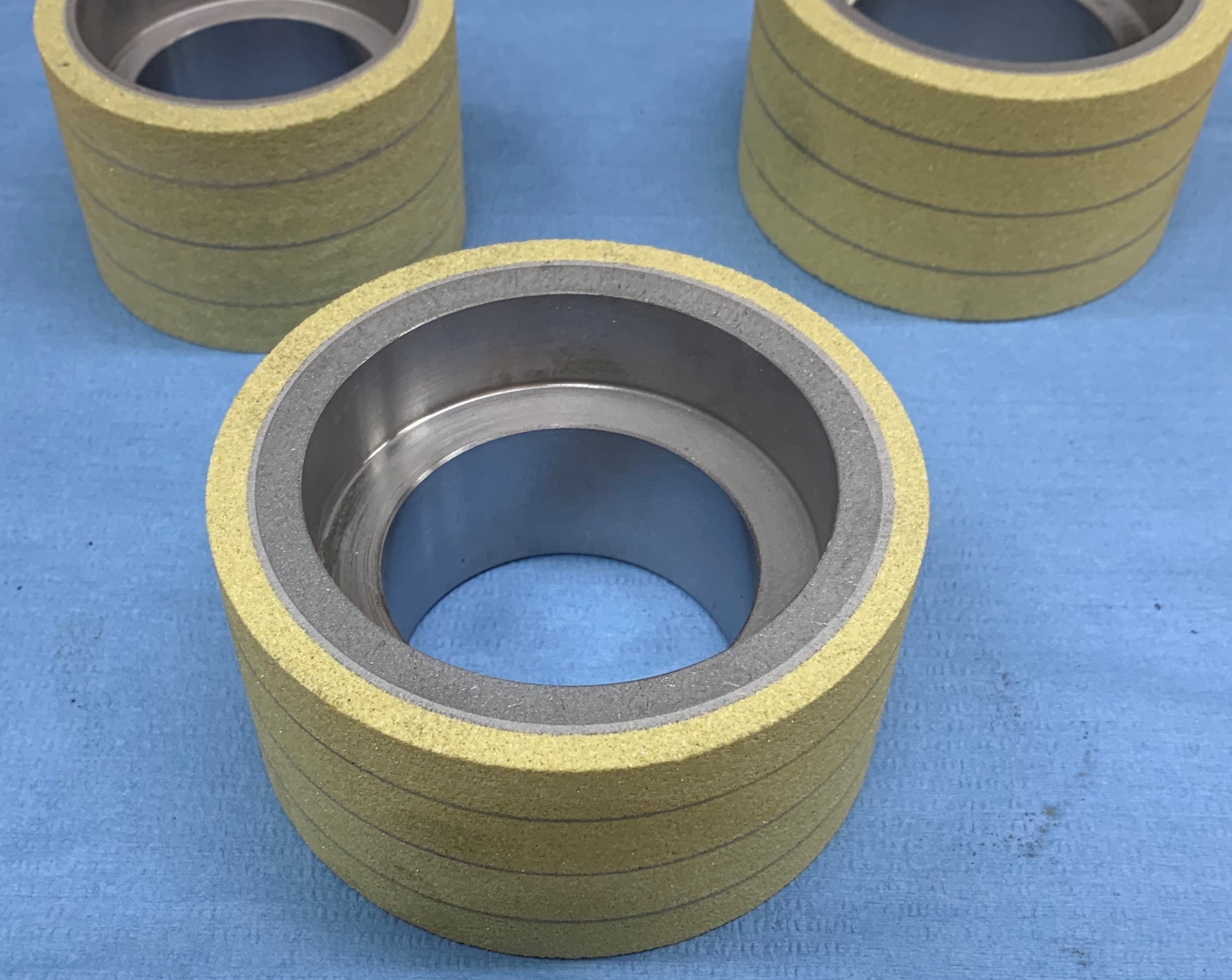

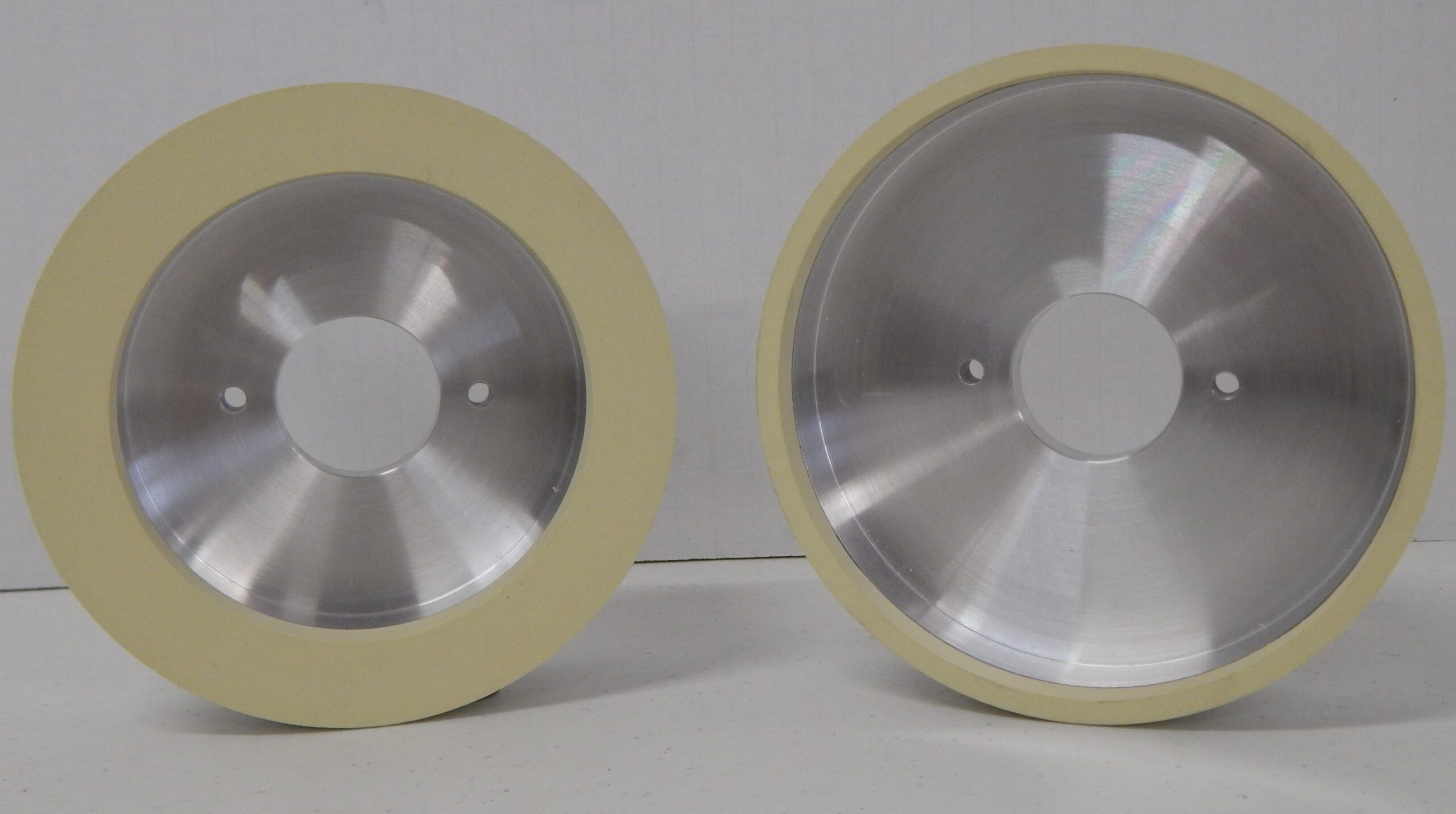

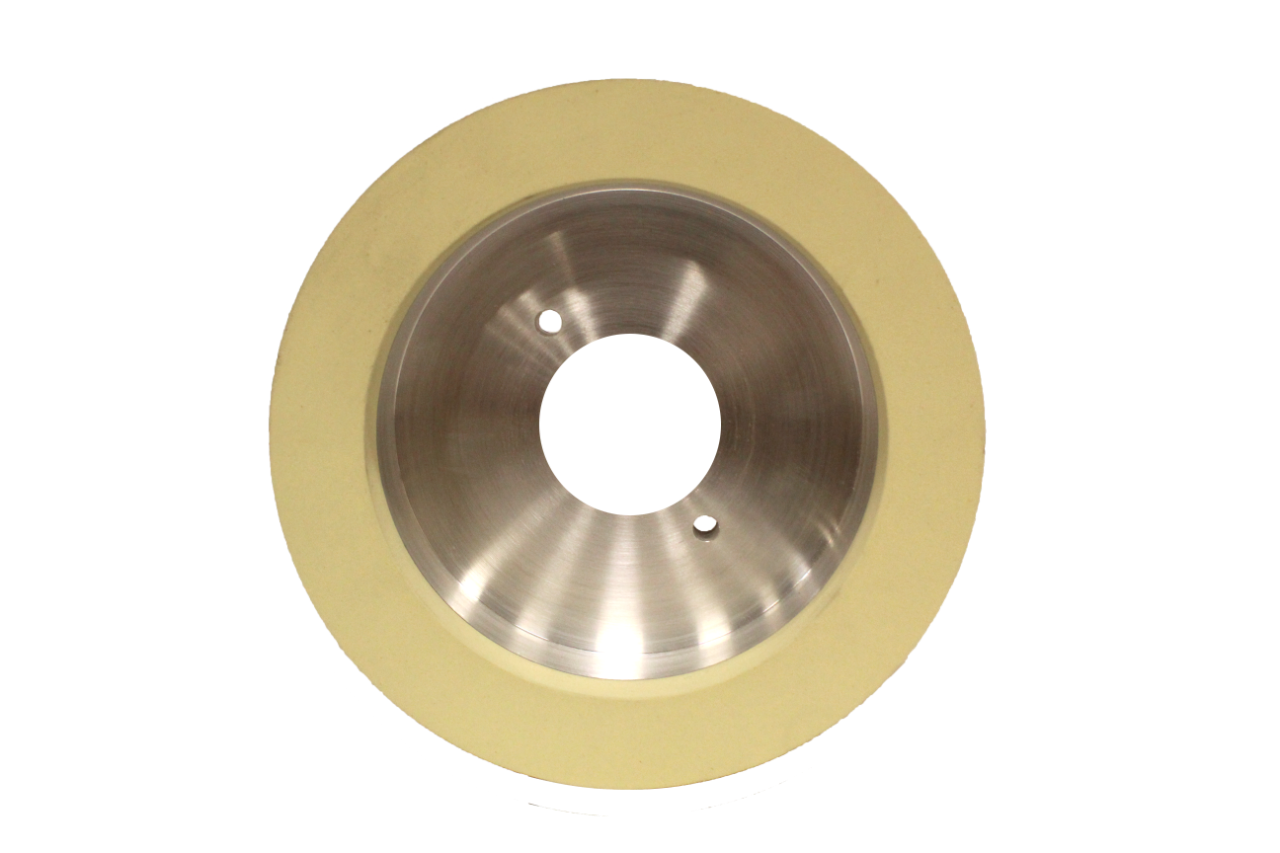

Advanced Superabrasives, Inc.’s (ASI) Vitrified diamond and CBN grinding wheels are manufactured to create higher levels of porosity.

This provides our grinding wheels the ability to withstand great forces of pressure without distortion, and to attain high stock removal rates. It also helps to carry coolant to the grind zone which reduces the risk of thermal heat transfer, which can cause damage to the products and make holding tight tolerances a challenge.

ASI’s Vitrified grinding wheels are an ideal choice for ball screw grinding, grinding of cast iron or steel parts such as injection nozzles, compressor blades and vanes, PCD and PCBN tool and insert grinding, plus OD grinding of automotive and aerospace industry parts.

Usage Applications:

ASI’s Vitrified Diamond & CBN Grinding wheels can be utilized in numerous grinding applications. These include but are not limited to:

- Medical Device and Instrument Manufacturing

- PCD & PCBN Tool Grinding

- Ball Screw Grinding

- Cam & Crankshaft Grinding

- Automotive Manufacturing

- Aerospace Parts

- Wind Turbine Manufacturing

“ASI’s 1V1R grinding wheel decreased our cycle time considerably. The radius holds up really well, and holds up better than the standard bond we were using.”

Wayne Taylor – Amamco Tool & Supply Co.

Vitrified Grinding Wheels in Detail

Material Application:

ASI’s vitrified wheels provide great versatility and can be utilized on multiple different material types. These include but are not limited to:

- Cast Iron

- Alloy and Hardened Carbon Steel

- Stainless Steel

- PCD & PCBN

- Ceramic

- Tungsten Carbide

- Cermet

Common Wheel Styles Used:

- 1A1

- 1F1

- 1E1

- 3A1

- 6A2

- 2A2T

- 6A9

Benefits:

ASI’s vitrified wheels provide the following benefits for our customers:

- Higher levels of porosity

- Less risk of thermal transfer damage

- Ease of dressing

- High production outputs with longer wheel life

You may also be interested in:

TruDress Ultra II

To expand our offering of the total grinding solution to our customers, we also manufacture a lineup of truing and dressing machines. All machines are designed in-house with an emphasis on simplicity of use and long-term durability.

MT-30

Advanced Superabrasives, Inc. has designed and manufactures a Coolant Filtration System that quickly removes carbide, cermet, cast metals, glass and ceramic grinding particulates from oil and/or water based synthetic coolants.

Electroplated

ASI’s Electroplated Diamond and CBN grinding wheels are coated by nickel alloy that securely anchors the crystal to provide excellent form holding and life, with no requirement of dressing.