Advanced Superabrasives, Inc. has designed and manufactures a Coolant Filtration System that quickly removes carbide, cermet, cast metals, glass and ceramic grinding particulates from oil and/or water based synthetic coolants.

Machine specifications:

- Cleans up to 30 gallons (120 Liters) per minute.

- Works in oil and water based synthetic coolants.

- Available for portable or fixed position usage.

- Self-priming centrifugal pump.

- Electrics: 240/480 volts – 3 phase 60 Hz or 400-volt 3 phase 50 Hz.

- In Stock Filters Available in 5, 10 and 25 microns.

“ASI’s product quality is excellent and the outstanding technical support provided for our challenging ceramic grinding applications sets them apart from most of our other suppliers.”

Brian H. Gold – Superior Technical Ceramics Corp.

The Model MT-30 in Detail

Available downloads

Client testimonial

“The, system is working phenomenally! We are really happy with it. There will be very little down time now in regards to scraping out the saw’s pan of the usual 4” of Macro grit every 1.5 – 2 months and having to spend money on refilling it with coolant. Now there is just a little sediment since we implemented the filtration system.”

Mike, A Plastics Manufacturer

Example results after investing in the MT-30-Filtration System

Results from a Major Ceramics Manufacturer

“Just wanted to give you some preliminary results on the test filtration unit that we have on the Royal Master. Here is a Return on Investment (ROI) and Rate of ROI. It should only take me 2.25 months to recoup the investment costs based on the gains that we are seeing.”

| ROI Analysis | |

| Unit Cost | $6,250.00 |

| Installation | $3,250.00 |

| Filters | $87.52 |

| New Coolant | $1,297.98 |

| Total | $10,885.50 |

| ROI | 433.71% |

| Cost Savings/Month | $4,841.44 |

| Rate of ROI (months) | 2.25 |

See the MT-30 in Action

You may also be interested in:

TruDress Ultra II

To expand our offering of the total grinding solution to our customers, we also manufacture a lineup of truing and dressing machines. All machines are designed in-house with an emphasis on simplicity of use and long-term durability.

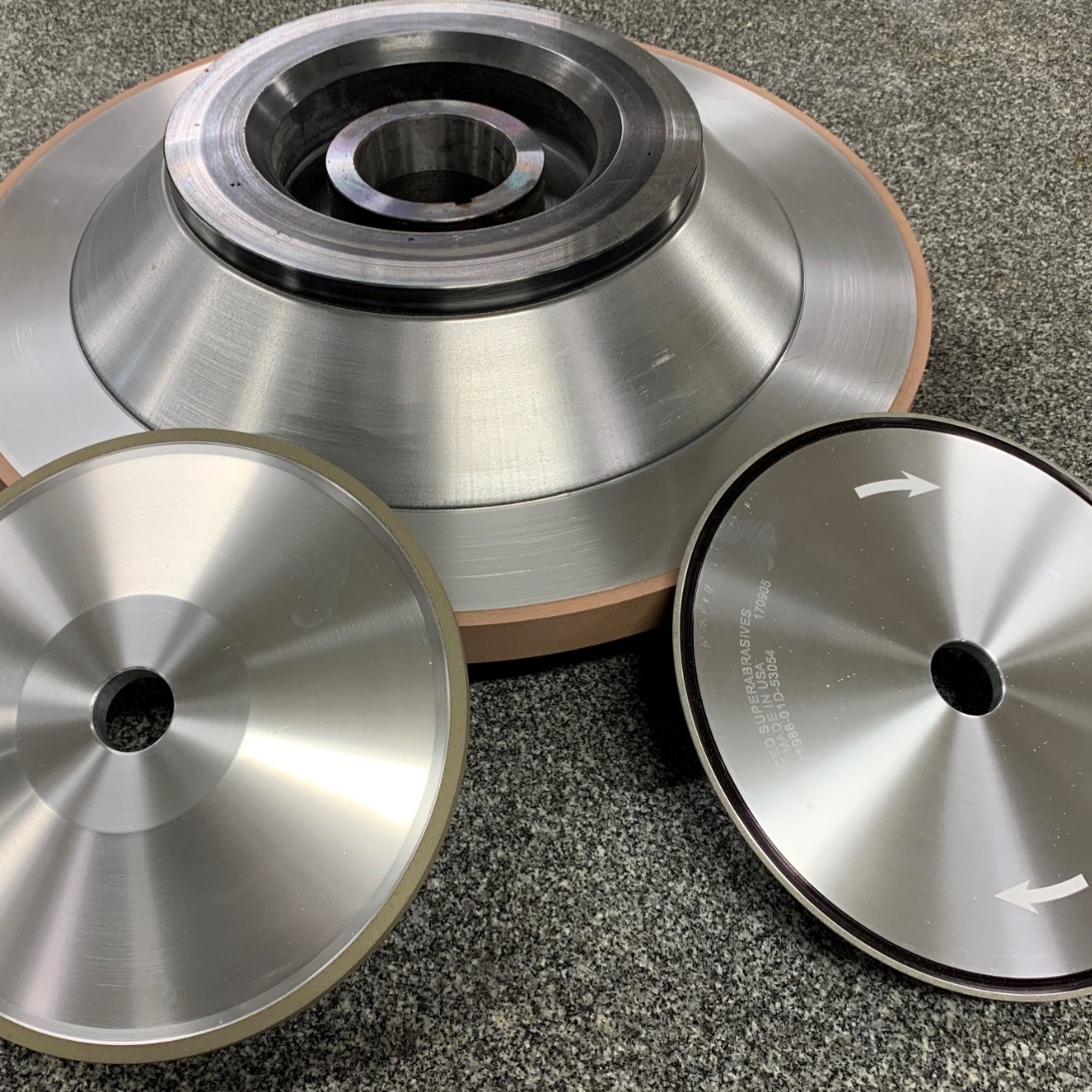

Resin Bond

ASI’s resin bond wheels are ideal for grinding hardened steel, tungsten carbide, PCD, PCBN, optical glass, ruby, ceramics and many other materials

Dressing Wheels

Advanced Superabrasives, Inc. stocks a variety of dressing wheels to keep your diamond and CBN grinding wheels sharp and free cutting for optimum efficiency. Our dressing wheels are made of aluminum oxide or silicon carbide, and vary in grit, hardness, and grain structure.